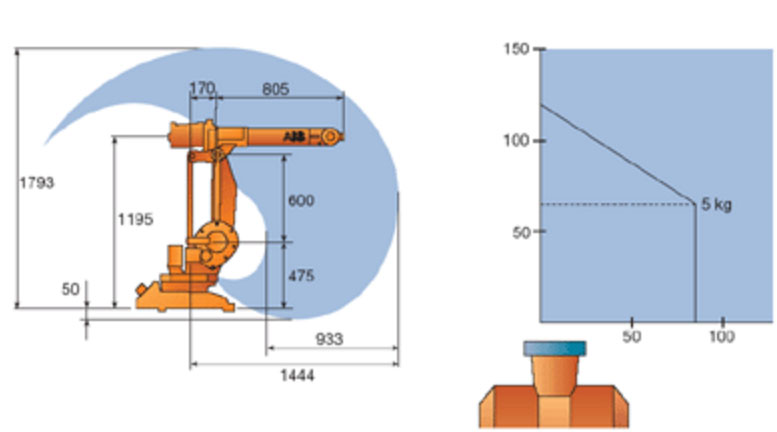

ABB Arc Welding Robot IRB 1410 Load 5kg

Time:2017-1-12 15:21:00 Views:11518

ABB Industrial Robot. Products include: palletizing robots, arc welding robots, bending robots and so on. ABB robots are one of the company's main products, which are popular in European, American and Asian markets. Shanghai Guilun distributes ABB Robots for ten years. We are your trustworthy partner to provide customers with cost-effective product solutions based on their actual conditions.+86 21 56519159

IRB 1410 5kg ABB Industrial Robot

IRB 1410 has been tested in arc welding, material handling and process applications. Since 1992, more than 14,000 sets of IRB 1410 have been installed worldwide. IRB 1410 has excellent performance, remarkable economic benefits and short capital recovery cycle.

Reliability - strong and durable

IRB 1410 is famous for its solid and reliable structure. Other advantages it brings are low noise level, long routine maintenance interval and long service life.

Accuracy - Stable and reliable

Excellent control level and path-following accuracy (+0.05 mm) ensure excellent quality of work.

坚固 -- 及时应用Ruggedness - timely application

The robot has a large working range and a long arrival distance (up to 1.44 m). The load-bearing capacity is 5 kg, and the upper arm can bear additional load of 18 kg. This is unique among similar robots.

High Speed--Shorter Working Cycle

Robot body is strong, equipped with fast and accurate IRC5 controller, which can effectively shorten the working cycle and improve productivity.

Arc welding - wire feeding mechanism integrated on the robot arm, with the arc welding function used by IRC5 and the patented single point programming teaching device, is suitable for the application of arc welding.

technical parameter

|

Specifications

|

carrying capacity

|

Distance of arrival

|

Installation mode

|

Protection level

|

|

IRB 1410

|

5 kg

|

1.44 m

|

Floor type

|

Equipment needs drying environment

|

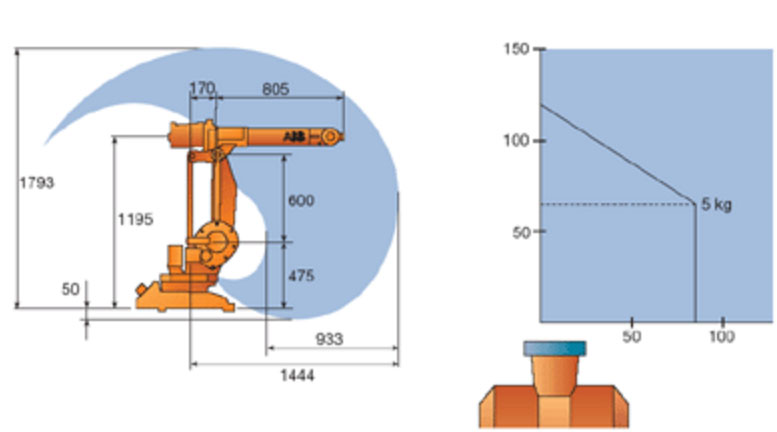

Working Range and Load Diagram